For low to high heat demand, boilers are available in the output range of 750 to 19,200 kW.

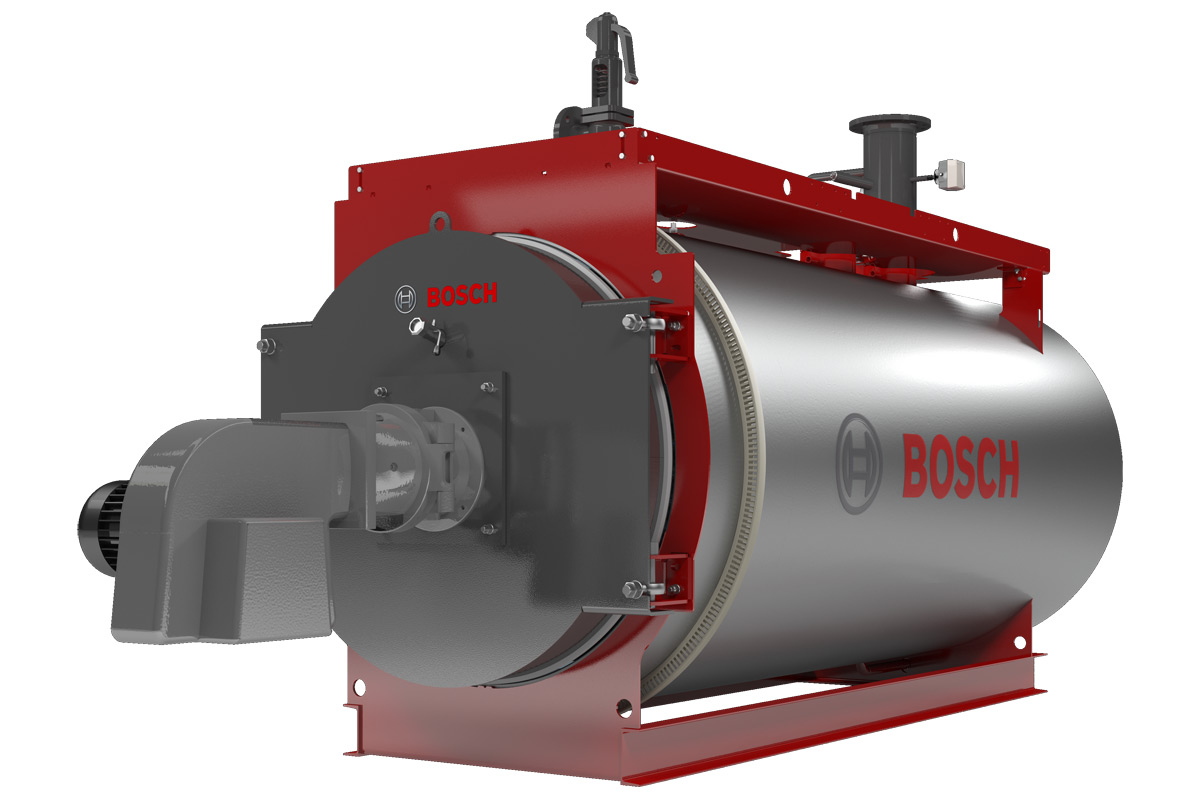

Following the success of the Unimat UT boiler, Bosch is expanding its range with the Unimat UT-M model, which is ideal for medium to high temperature requirements.

The proven UNIMAT three-path design has been in use for decades. The UT-M boiler is available in various sizes and can be used in systems with several boilers. It is CE-approved and built and equipped in accordance with the European Pressure Equipment Directive.

| Type | UNIMAT UT-M |

|---|---|

| Transfert de chaleur | Eau chaude haute pression |

| Construction | Chaudière à un tube foyer à triple parcours |

| Puissance | 750 à 19 200 kW |

| Limite de surpression | jusqu'à 16 bars |

| Température maxi. | jusqu'à 190 °C |

| Combustible | Fuel, gaz |

The UT-M proves its outstanding performance in boiler rooms for the supply of heat to remote or local networks. The superheated water boiler is also used in commercial and industrial heating systems.

- Triple-path construction

- Standardised efficiency without flue gas heat exchanger up to 95 %, with condensing heat exchanger up to 105

- Effective insulation, high efficiency

- Approved for low return temperatures from 50°C

- Suitable for all burners

- Low-emission combustion through the use of state-of-the-art combustion systems and careful selection of the best boiler/burner combination

- Easy maintenance thanks to a fully pivoting front door

- Robust, reliable and incomparably durable

- No minimum burner load to keep the flue gas side dry

- Space-saving routing of the flue pipe

- Permissible high temperature difference of up to 50 K

The fire tube ends in a flooded gas inversion chamber which leads into the first flue gas circuit. Smoke circulation is free in both the first and second smoke circuits. The rounded design is very functional as it provides optimal pressure resistance. The firebox, water volumes, radiation and convection surfaces are optimally dimensioned and matched to each other.

The front door of the boiler is fully hinged, with a choice of right or left hinge. The entire boiler section is easily accessible. This makes maintenance, cleaning and inspection easy. The high-quality mineral wool insulation of the entire heating body and the special thermal insulation of the front door ensure low radiation losses. On request, the heat generator can be equipped with a flue gas heat exchanger or a condensation heat exchanger at the factory.

The European approval according to the Pressure Equipment Directive allows an operating and safety temperature level of up to 190 °C.

The UT-M boiler is offered with accessories as fully functional units. The high-quality equipment includes the boiler pressure vessel, the burner block, the flue gas heat exchanger or the condensing heat exchanger and the control and safety technology, which is already wired with the integrated connection box.

Base equipment

Variable equipment according to the customer's wishes

Associated boiler room elements

- Water conditioning module WTM

- Flue gas heat exchanger ECO 1/7

- Flue gas heat exchanger ECO 6 for individual installation

- Flow/return connection SP/RP

- Thermal return temperature protection RTS

- Gas control module GRM

- Oil circulation module OCM

- Oil supply module OSM

- System management system SCO