With this system, the combustion air is preheated and the gas temperature is reduced. The efficiency is increased.

When installing steam boilers with economizers, the new air preheating system is the ideal solution to increase efficiency, especially in cases where the integration of a flue gas condenser is impractical due to certain processes.

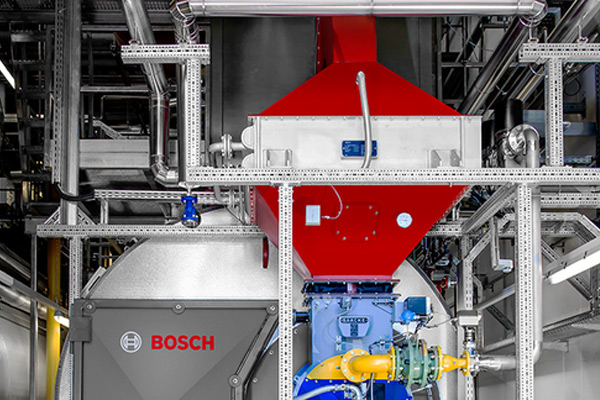

The Bosch air preheating system is available for tube boilers, with single or double flames, and duobloc burners. This system is very economical and allows the boiler to have a steam capacity of 5 t/h. The fan can be installed on top of the boiler. Thanks to its compactness, the installation requires very little space. Moreover, the investment in these systems is amortized in only 1.5 to 2 years.

- Improved system efficiency

- Reduction of fuel consumption

- Reduction of pollutant emissions

- Lower capital costs compared to conventional solutions

- Reduced maintenance and service costs

- Significantly reduced payback period

- High quality Bosch standartis system

With the Bosch system, a portion of the hot water flow is used to raise the temperature of the combustion air. The cooled water then increases efficiency by further reducing the flue gas temperature in the downstream economizer.

The air preheating system consists of a three-way valve, a gas side heat exchanger and an air side heat exchanger. If we compare with traditional double circuit systems, there is no need to add a circulation pump, expansion tank and various electronic control and safety devices. Thus, the costs for investment, regular maintenance and repairs are significantly reduced.